x

- More +

Automobili Lamborghini, the iconic Italian sports car manufacturer, has been at the forefront of automotive innovation for over six decades. Now, the company has unveiled a new technical solution that is set to revolutionize the industry. The LB744 is the company’s first hybrid plug-in V12 High Performance Electrified Vehicle (HPEV) and is based on a […]

Automobili Lamborghini, the iconic Italian sports car manufacturer, has been at the forefront of automotive innovation for over six decades. Now, the company has unveiled a new technical solution that is set to revolutionize the industry.

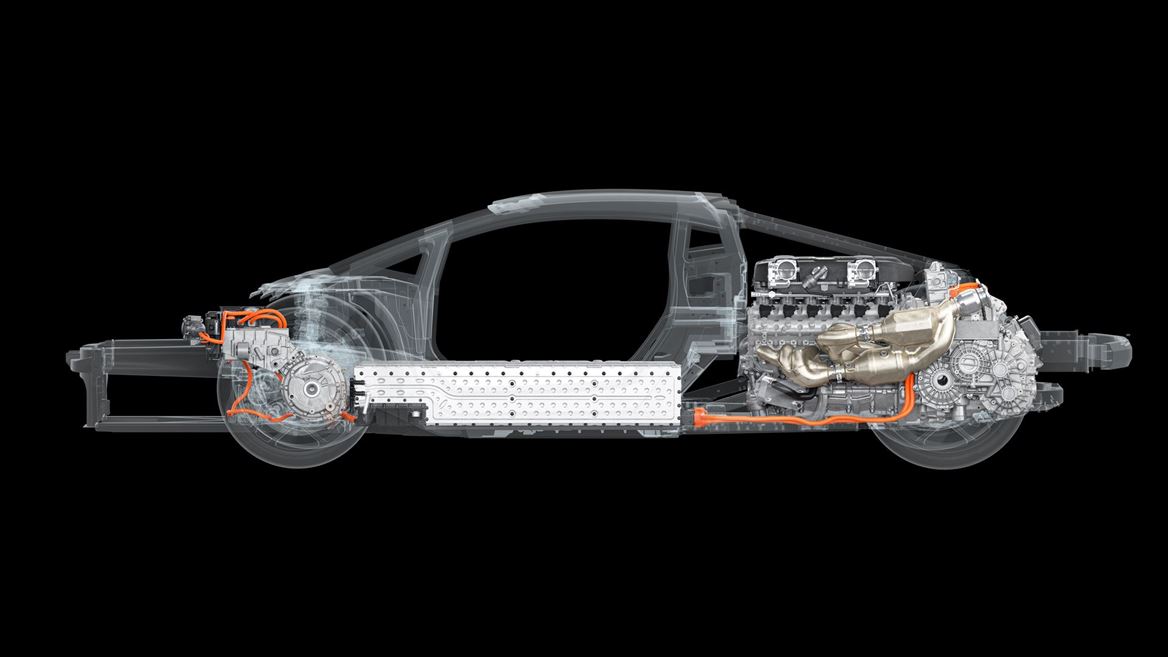

The LB744 is the company’s first hybrid plug-in V12 High Performance Electrified Vehicle (HPEV) and is based on a new aeronautics-inspired chassis, the “monofuselage”. This innovative design features a monocoque made entirely of multi-technology carbon fiber, with a front structure in Forged Composites. This special material is made of short carbon fibers soaked in resin and was patented and used by Lamborghini in its first structural applications in 2008.

The monofuselage is a significant step forward from the Aventador in terms of torsional stiffness, lightweight qualities, and driving dynamics. The LB744 is also the first super sports car to be fitted with a 100% carbon fiber front structure, with the front cone structures also made of carbon fiber to ensure a level of energy absorption that is significantly higher than a traditional metal structure.

In fact, the LB744 monofuselage is 10% lighter than the Aventador chassis, with the front frame being 20% lighter than its aluminum predecessor. Torsional stiffness has also been improved, with a value of 40,000 Nm/°, up 25% compared to the Aventador, ensuring best-in-class dynamic capabilities.

The design concept behind the new monofuselage is based on maximum integration between components. This is optimized thanks to the extensive use of Forged Composites technology and the development of the monolithic rocker ring. The single-element ring-shaped component is made of CFRP (Carbon Fiber Reinforced Plastic) and forms the supporting structure of the car. The rocker ring encloses and connects the Forged Composites elements such as the tub, the front firewall, and A pillar.

The LB744 represents a new “year zero” in relation to the use of carbon fiber in car production, summed up in the acronym AIM (Automation, Integration, Modularity). “Automation” refers to the introduction of automated and digitalized processes into material transformation, while preserving traditional Lamborghini manufacturing such as in the discipline of composites. “Integration” relates to the integration of several functions into a single component through the development of compression molding. Finally, “Modularity” refers to making the applied technologies modular and therefore more flexible and efficient to respond to all the product requirements and characteristics.

Lamborghini has also optimized efficiency and increased sustainability during the manufacturing process by reducing the energy consumption of cooling equipment and the quantity of waste materials. The more traditional technology of autoclave composite production with pre-impregnated material was retained for the roof construction. The autoclaved carbon fiber meets high technical, aesthetic, and quality requirements, complemented by craftsmanship in the highly specialized hand lay-up process, which results from years of quality-driven in-house production of composite material components.

The rear chassis of the LB744 is made of high-strength aluminum alloys and features two important hollow castings in the rear dome area that integrate the rear suspension’s shock towers and powertrain suspension into a single component with a closed inertia profile. This guarantees a significant reduction in weight, an increase in rigidity, and a substantial reduction in welding lines.

TechReleased is one of the leading source of technology information and a newspaper which is dedicated for technology news and releases, it is one of the few online sources that provides all the technology news from the globe.